-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

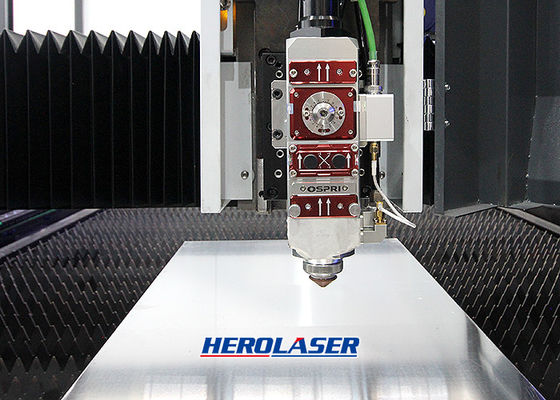

Horizontal 110m/Min Sheet Metal Fiber Laser Cutting Machine , 3015 Laser Cutter

| Model | ML-CZ-3015FB | Acceleration Of Idle Operation | 1.0G |

|---|---|---|---|

| Machine Tool Load | 1000KG | Synthesis Speed | 110m/min |

| Positioning Accuracy | ±0.03mm/m | Repeat Accuracy | ±0.02mm/m |

| Highlight | 110m/min Sheet Metal Fiber Laser Cutting Machine,3015 Sheet Metal Fiber Laser Cutting Machine,3015 laser cutter |

||

3015 Fiber laser Metal Sheet Cutting Machine 1500W-20000W

Working Principle of 3015 Laser Metal Sheet Cutting Machine

The horizontal laser beam emitted by the laser changes into a vertical downward laser beam through a reflector of 45 degrees, and then converges through the lens to form a tiny spot at the focus. When the workpiece at the focus is irradiated by the laser spot with high power density, a part of the high temperature above 10000 degrees will occur, causing the workpiece to vaporize instantly, then with the help of the cutting gas, the vaporized metal is blown away, and the workpiece is shot through into a very small hole. With the movement of the CNC machine tool, countless small holes are connected to form the shape to be cut. Because the frequency of laser cutting is very high, the joint of each small hole is very round, and the finished product is very smooth.

Equipment Features of 3015 Laser Metal Sheet Cutting Machine

- High stability, low power consumption and long service life;

- Equipped with emerging technology, automatic focusing cutting head, easy and intelligent operation;

- High end intelligent bus system with excellent performance;

- It can directly draw or edit the graph track in the software processing system;

- Good cutting quality, high precision, no mechanical deformation, smooth and beautiful appearance;

- High-end configuration, powerful function and high cost performance.

![]()