-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

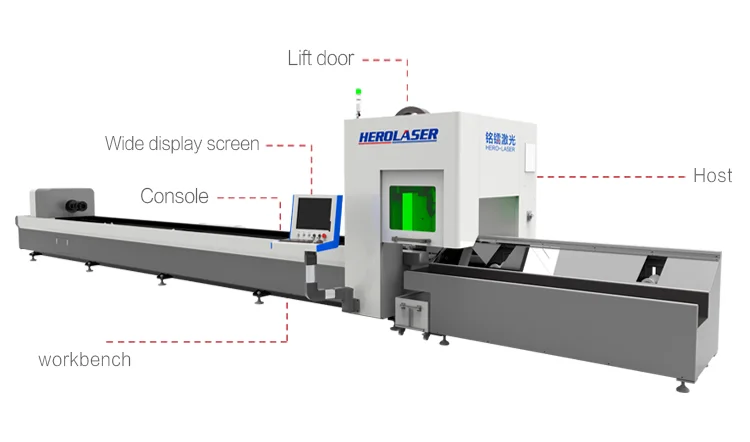

Automatic Feeding Pipe Laser Cutting Machine For Metal Stainless Steel Aluminum

| Laser Source | 1500W | Gear And Rack | APEX/YYC |

|---|---|---|---|

| Cutting Head | OSPRI | Pneumatic Components | SMC, AirTAC |

| Laser Wave Length | 1070nm | Repeated Position Accuracy | ≤±0.03mm |

| Positioning Accuracy | ≤±0.05mm | ≤±0.05mm | ≤150m/min |

| Max Speed Of Y-axis | ≤120m/min | Max Speed Of Z-axis | ≤65m/min |

| Power Supply | AC380V±5%50Hz | Dimension Size | 11000*2500*2300(mm) |

| Highlight | YYC Pipe Laser Cutting Machine,1500W Pipe Laser Cutting Machine,120m/min Laser Tube Cutting Machine |

||

CNC Fiber Laser Cutting Machine For Metal Stainless Steel Aluminum Copper Processing

Automatic Feeding Tube Pipe Cutting Machine For Metal Stainless Steel Aluminum

Laser cutting uses a high-power density laser beam to quickly heat the material to vaporization temperature and evaporate to form a hole, move the beam to form a slit, so that realize the materials cutting based on this

Purple Horn small area high precision cutting machine also achieves high-precision cutting, no tool wear, low heat impact, fast speed, automatic positioning, automatic correction and other functions.

Stable, mature technology, high cutting efficiency, small footprint, flexible application with full-time cutting, high utilization

of the materials, strong expandability , and very flexible

2. High-precision host

Precision linear guide, high precision positioning, less wear; can keep high precision for a long time, easy and interchangeable

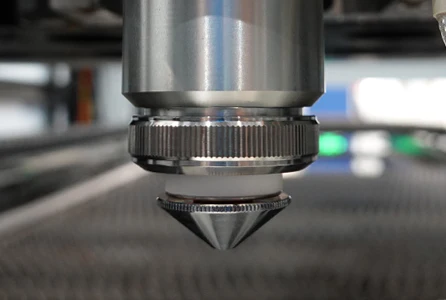

3. Laser cutting head

The laser cutting head is equipped with a sensitive bus-type capacitor, which can be adjusted to the ideal focal length to ensure

the cutting efficiency and cutting effect

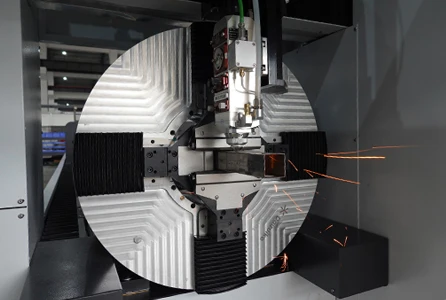

4. Precise cutting

Realize the precise cutting and nearly without error and the cutting surface is smooth and flat

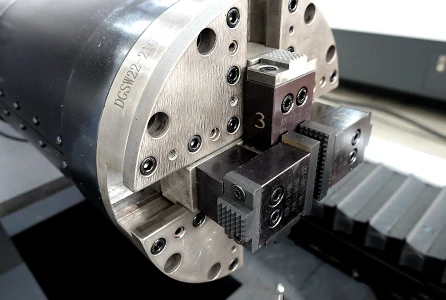

Special support frame can avoid pipe sagging and deformation, improve cutting accuracy and prolong the service life of chuck

material surface to ensure the perfection of the workpiece.

2, Very low operation and maintenance costs

3, The laser cutting head will not contact the material surface and will not scratch the workpiece

4, The front chuck maintains the full stroke without changing the claw

5, High speed idle stroke, high acceleration, fast cutting response, not easy to burn corners

6, The rear chuck vacuums at the rear and the front chuck vacuums at the side. The tube wall is cleaner

and there is less cutting dust and smoke

7, The height of the feeding fixed support wheel can be adjusted manually, and the blanking is a

combination of follow-up support and slope sliding

8, High-speed and high-quality laser cutting can be performed on various profiles such as round pipe, square pipe, rectangular

pipe, waist round pipe, angle steel and C-section steel

9, The pipe cutting section is smooth without burr, slag, blackening and yellowing, which can easily

realize the cutting of various complex graphics

research and development, production and marketing of laser equipment group of companies, has formed a complete series of

industrial laser equipment supply platform.

With a team of professional technical personnel,rich management experience, clear development direction to ensure our rapid growth

in the rapid development of the laser industry,we have established branches in Jiangsu, Zhejiang,Shandong, Chongqing and other

regions in China, and we have exported to 60 countries and have overseas agents in 10 countries. Our main products is Laser

Cleaning Machine / Laser Marking Machine / Laser Welding Machine / Laser Cutting Machine.

Products are widely used in electrical appliances, mobile communications, hardware products, tool accessories, precision

equipment, jewelry, glasses and watches, integrated circuits, craft gifts, plastic molds, medical equipment and other industries.

Production of Laser Welding series, Laser Cleaning series, Laser Cutting series and Laser New energy automation, etc.

2. What are the payment methods of Purple Horn Company?

T/T, LC, CAD, OA, Trade Insurance, Alibabapay

3. Does Purple Horn accept Acceptance?

Yes, we accept bank acceptances within 6 months, not commercial acceptances.

4. Can I visit the factory?

Available to have a visit to our factory at any time.

5. What can I get with the purchase of equipment?

Each machine has a set of standard accessories.

6. Can I go to the factory to test the machine before shipment?

Of course you can.

7. How is the delivery and shipment?

Ship in 7 days after 100% payment; Packaged with Plywood box.

8. How about your pre-sales service?

Provide quick response and free consulting services within 8 hours.

9. How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.