All Products

-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

-

Christopher RodriguezWe were always looking for the right technology to modify our industrial cleaning. In our search, we found Herolaser. The results and time to complete the cleaning exceeded our expectations. We now have found the right partner to make cleaning easy and without damage to the substrate.

Christopher RodriguezWe were always looking for the right technology to modify our industrial cleaning. In our search, we found Herolaser. The results and time to complete the cleaning exceeded our expectations. We now have found the right partner to make cleaning easy and without damage to the substrate. -

Cesare DuminucoActually we were not sure about the capacity and performance of laser welding since we had always been doing MIG and TIG in our workshop. We placed the first order after more than 3-month negotiation with Herolaser. Right now the machine is working pretty well with problems solved through online communication and videos guidance.

Cesare DuminucoActually we were not sure about the capacity and performance of laser welding since we had always been doing MIG and TIG in our workshop. We placed the first order after more than 3-month negotiation with Herolaser. Right now the machine is working pretty well with problems solved through online communication and videos guidance. -

James AdamsNice company to cooperate with, from the planning stage to project completion. Quick response to any pre-sales and after-sales questions. We are very satisfied with the supplied quality.

James AdamsNice company to cooperate with, from the planning stage to project completion. Quick response to any pre-sales and after-sales questions. We are very satisfied with the supplied quality.

Contact Person :

Felicia Zhou

Whatsapp :

+8617873657316

Automatic Platform Optical Fiber Laser Welder Soldering For Copper Aluminum SS

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Dimensions | 1500mm×1400×1900mm | Machine Weight | 400kg |

|---|---|---|---|

| Laser Power | 1500W | Average Load Power | 7.5 KW |

| Focal Spot Diameter | 0.15mm~0.45 Mm | Observing System | CCD + Red Light |

| Highlight | Aluminum Soldering Fiber Laser Welder,0.45mm Fiber Laser Welder,SS Automatic Laser Welding Machine |

||

Product Description

Parameter

![]()

Products Description

The laser welding head adopts the laser welding head independently developed by Purple Horn, which has very high

welding stability and flexibility, and can be rotated 360 degrees.

Laser welding machines use high-energy pulsed lasers to weld objects

The cooling system of the fiber laser welding machine is composed of temperature measuring device, water

circulation, radiator and deionized resin.

The temperature measuring device detects the water temperature in the water tank in real time and judges whether

the water temperature is too high.

If the temperature exceeds the upper limit, the system will automatically turn off the laser to avoid damage to the

laser.

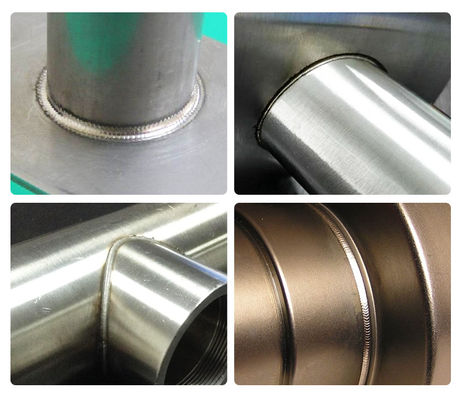

Sample Show

precision machinery

communications

handicrafts

Installation Instructions

Shenzhen Purple Horn Equipment Co., Ltd was established in 2004, is a national high-tech enterprise in China, engaged in the research and development, production and marketing of laser equipment group of companies, has formed a complete series of industrial laser equipment supply platform.

With a team of professional technical personnel,rich management experience, clear development direction to ensure our rapid growth in the rapid development of the laser industry,we have established branches in Jiangsu, Zhejiang,Shandong, Chongqing and other regions in China, and we have exported to 60 countries and have overseas agents in 10 countries. Our main products is Laser Cleaning Machine / Laser Marking Machine / Laser Welding Machine / Laser Cutting Machine.

Products are widely used in electrical appliances, mobile communications, hardware products, tool accessories, precision equipment, jewelry, glasses and watches, integrated circuits, craft gifts, plastic molds, medical equipment and other industries.

With a team of professional technical personnel,rich management experience, clear development direction to ensure our rapid growth in the rapid development of the laser industry,we have established branches in Jiangsu, Zhejiang,Shandong, Chongqing and other regions in China, and we have exported to 60 countries and have overseas agents in 10 countries. Our main products is Laser Cleaning Machine / Laser Marking Machine / Laser Welding Machine / Laser Cutting Machine.

Products are widely used in electrical appliances, mobile communications, hardware products, tool accessories, precision equipment, jewelry, glasses and watches, integrated circuits, craft gifts, plastic molds, medical equipment and other industries.

Certification

Packaging & Shipment

Our Services

---Pre-Sales Services

① Free pre-sales 7*24 hours rapid response services / cousulting

② Free sample testing / inspection

③ Free design of fixtures as customers / distributor required

④ Strict quality control for our products

⑤ Quick delivery time

---After-Sales Services

① 2 year guarantee for laser source(people damaged are charged)

② Full technical support / by e-mail, call and video

③ Spare parts supply.

④ Free online training installation and operation

⑤ 12 hours quick feedback & after-sales services

⑥ ODM/OEM service

FAQ

1. What model does Purple Horn produce?

Production of Laser Welding series, Laser Cleaning series, Laser Cutting series and Laser New energy automation, etc.

2. What are the payment methods of Purple Horn Company?

T/T, LC, CAD, OA, Trade Insurance, Alibabapay

3. Does Purple Horn accept Acceptance?

Yes, we accept bank acceptances within 6 months, not commercial acceptances.

4. Can I visit the factory?

Available to have a visit to our factory at any time.

5. What can I get with the purchase of equipment?

Each machine has a set of standard accessories.

6. Can I go to the factory to test the machine before shipment?

Of course you can.

7. How is the delivery and shipment?

Ship in 7 days after 100% payment; Packaged with Plywood box.

8. How about your pre-sales service?

Provide quick response and free consulting services within 8 hours.

9. How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.

10. How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.

Production of Laser Welding series, Laser Cleaning series, Laser Cutting series and Laser New energy automation, etc.

2. What are the payment methods of Purple Horn Company?

T/T, LC, CAD, OA, Trade Insurance, Alibabapay

3. Does Purple Horn accept Acceptance?

Yes, we accept bank acceptances within 6 months, not commercial acceptances.

4. Can I visit the factory?

Available to have a visit to our factory at any time.

5. What can I get with the purchase of equipment?

Each machine has a set of standard accessories.

6. Can I go to the factory to test the machine before shipment?

Of course you can.

7. How is the delivery and shipment?

Ship in 7 days after 100% payment; Packaged with Plywood box.

8. How about your pre-sales service?

Provide quick response and free consulting services within 8 hours.

9. How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.

10. How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.

Recommended Products