-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

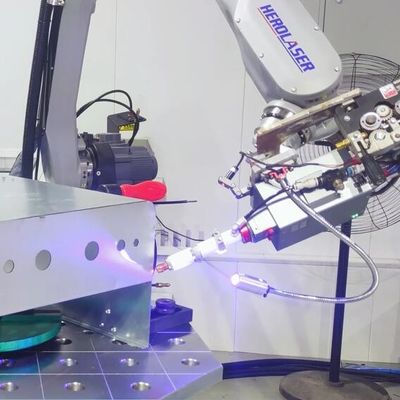

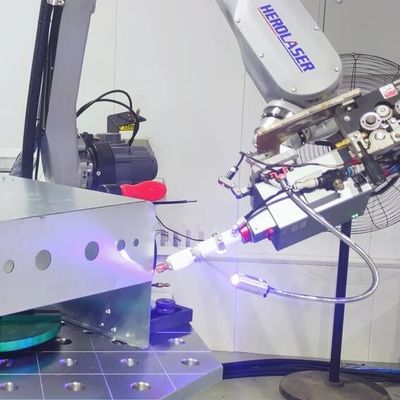

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

Purple Horn 3000w Robot Automatic Laser Welding Machine IPG Source

| Brand | Purple Horn | Laser Source Brand | IPG |

|---|---|---|---|

| Focal Spot Diameter | 0.1-3 Mm | Power Demand | 380V±10%,50Hz/60Hz AC |

| Cooling | Water Cooling | Wavelength | 1070 Nm |

| Highlight | Automatic Laser Welding Machine 3000w,3mm Automatic Laser Welding Machine,IPG Robot Laser Welding Machine |

||

![]()

Purple Horn 3000w Robot Automatic Laser Welding Machine

Model profile

Laser welding robot takes semiconductor laser as the welding heat source, which makes it more and more widely used in the

welding of camera parts of mobile phones, laptops and other electronic devices.

![]()

![]()

Model characteristics

1. It is non-contact. The minimum point diameter formed by laser can reach 0.1mm, and the minimum tin feeding device can reach 0.2mm. It can realize the welding of micro pitch packaging (mounting) components.

2. Because it is a short time of local heating, the thermal effect on the substrate and surrounding parts is very small, and the quality of solder joints is good.

3. No consumption of soldering iron head, no need to replace the heater, and high working efficiency during continuous operation.

4. When conducting lead-free welding, it is not easy to have solder joint cracks.

5. The surface temperature of the solder shall be measured by non-contact method, but not by the temperature measurement method actually contacting the solder head.

![]()

| N | Item | Parameter |

| 1 | Equipment name | Double position robot laser welding machine |

| 2 | laser power | 300~3000W |

| 3 | Laser wavelength | 1070NM |

| 4 | Laser wavelength | 10M |

| 5 | operation mode | Continuous / modulation |

| 6 | Welding speed range | 0~120mm/s |

| 7 | Cooling water machine | Industrial constant temperature water tank |

| 8 | Working environment temperature range | 15~35°C |

| 9 | Working environment temperature range | <70% No condensation |

| 10 | area covered | 1600*3000mm(Manipulator and worktable) |

| 11 | Arm length | 1400mm |

| 12 | working voltage | three-phase380V |

| 13 | Spatial positioning accuracy | ±0.05mm |

APPLICATION

The laser welding robot system has been more and more widely used in the welding of camera parts, LCD parts, micro motors,

micro transformers and other parts of electronic devices such as mobile phones and laptops, as well as in LCD TV, high-end

digital cameras, aerospace military manufacturing, high-end automotive parts manufacturing and other fields.

![]()

![]()

FAQ

1. How is the payment?

30% deposit before production and the balance 70% before shipment

2. How is the delivery and shipment?

Ship in 7 days after 100% payment

Plywood box packaging

3. How will you guarantee aftersales services?

We offer two warranty for laser source, one year for whole machine and lifetime maintenance services.

Engineers available to service machinery overseas

Free technical training in our factory

Free sample can be sent to you

Professional technical team 24 hours online

4. How about your presales service?

Speeding offer within 8 hours quick response and free consulting

Free sample marking or testing is available

Progressing solution design to all clients, including distributors and end users