-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

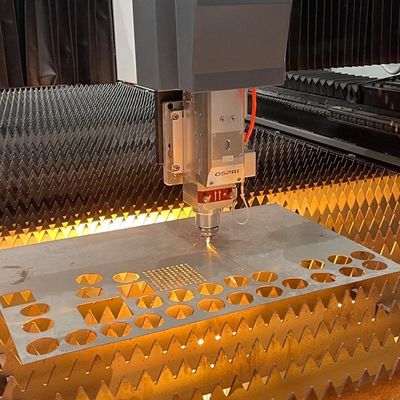

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

IPG Purple Horn 1000w CNC Fiber Optic Laser Cutter For Metal SS

| ML-C6-QFS | 1064nm~1074nm | Laser Wavelength | ≤20m/min |

|---|---|---|---|

| Max Speed Of X Axis | ≤20m/min | Max Speed Of Z Axis | AC220V, ±5% 50Hz |

| Power Supply | AC220V, ±5% 50Hz | Dimension | 1880mm*1450mm*2100mm |

| Highlight | 1000w Fiber Optic Laser Cutter,SS Fiber Optic Laser Cutter,IPG Laser Cutting Equipment |

||

-------------------------Product informatioin------------------------------------

Laser cutting is to use the high power density laser beam to make the material quickly heated to the vaporization temperature and evaporate to form a hole, and move the beam to form a slit to complete the cutting of the material. Mingradium laser small format precision cutting machine, on this basis, also highly realizes the functions of high precision cutting, small tool free wear

heat effect, fast speed, automatic positioning, automatic correction.

![]()

-------------------------Product Parameters-------------------------------------

| Optical performance parameter | |

| Laser source wavelength | ML-CB-4020FA-IW |

| Output power rate of the Laser source | 1070nm |

| Effective cutting area | 600mm*600mm |

| Cutting thickness (depend on Laser source power) | Carbon ≤8mm;Stainless Steel ≤4mm; |

| Aluminum Alloy ≤2mm; Copper ≤2mm; | |

| Positioning accuracy | ≤±0.03mm |

| Repeated position accuracy | ≤±0.02mm |

| Max speed of X-axis | ≤20m/min |

| Max speed of Y-axis | ≤20m/min |

| Max speed of Z-axis | ≤17m/min |

| Synthesis speed | ≤20m/min |

| Max accelerated speed | 0.3G |

| Bearing weight | 300KG |

| Electric demand | AC220V±5%50Hz |

| Total Power consumption | 6KW-25KW |

| Dimension | 1880*1450*2100(mm) |

| Machine weight | 1200KG |

| Support Graphical format | DXF |

-------------------------Details of Product-----------------------------------------

![]()

![]()

![]()

-------------------------Advantages of laser cutting---------------------------

1. Good cutting quality. Because of the small laser spot, high energy density and fast cutting speed, laser cutting can achieve good cutting quality.

2. The incision is thin and narrow, both sides of the cutting seam are parallel and perpendicular to the surface, and the dimension accuracy of the cutting parts is high. The cutting surface is smooth and beautiful, and can even be used as the last processing procedure. Parts can be directly used without machining.

3. The optical fiber laser cutting machine has no deformation in processing, and the material adaptability is good. No matter what the material is, it can be cut by laser precision rapid prototyping in one time. With its narrow cutting seam and good cutting quality, it can achieve automatic cutting layout and nesting, improve the material utilization, and achieve good economic benefits.

4. Fast cutting speed, high degree of automation, simple operation, low labor intensity and no pollution.

---------------------------------Cutting Effect--------------------------------------------

![]()

-------------------------Applicable Industry------------------------------------------------

Moble Communications New Enengy lndustry

Glasses Machining

-------------------------After-sales Services------------------------------------------------

1. What model does Purple Horn produce?

Production of Laser Welding series, Laser Cleaning series, Laser Cutting series and Laser New energy automation, etc.

2. What are the payment methods of Purple Horn Company?

T/T, LC, CAD, OA, Trade Insurance, Alibabapay

3. Does Purple Horn accept Acceptance?

Yes, we accept bank acceptances within 6 months, not commercial acceptances.

4. Can I visit the factory?

Available to have a visit to our factory at any time.

5. What can I get with the purchase of equipment?

Each machine has a set of standard accessories.

6. Can I go to the factory to test the machine before shipment?

Of course you can.

7.How is the delivery and shipment?

Ship in 7 days after 100% payment; Packaged with Plywood box.

8. How about your pre-sales service?

Provide quick response and free consulting services within 8 hours.

9.How will you guarantee after-sales services?