-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

-

Christopher RodriguezWe were always looking for the right technology to modify our industrial cleaning. In our search, we found Herolaser. The results and time to complete the cleaning exceeded our expectations. We now have found the right partner to make cleaning easy and without damage to the substrate.

Christopher RodriguezWe were always looking for the right technology to modify our industrial cleaning. In our search, we found Herolaser. The results and time to complete the cleaning exceeded our expectations. We now have found the right partner to make cleaning easy and without damage to the substrate. -

Cesare DuminucoActually we were not sure about the capacity and performance of laser welding since we had always been doing MIG and TIG in our workshop. We placed the first order after more than 3-month negotiation with Herolaser. Right now the machine is working pretty well with problems solved through online communication and videos guidance.

Cesare DuminucoActually we were not sure about the capacity and performance of laser welding since we had always been doing MIG and TIG in our workshop. We placed the first order after more than 3-month negotiation with Herolaser. Right now the machine is working pretty well with problems solved through online communication and videos guidance. -

James AdamsNice company to cooperate with, from the planning stage to project completion. Quick response to any pre-sales and after-sales questions. We are very satisfied with the supplied quality.

James AdamsNice company to cooperate with, from the planning stage to project completion. Quick response to any pre-sales and after-sales questions. We are very satisfied with the supplied quality.

400 Watt Mold Laser Welding Machine , YAG Laser Welding Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Laser Welding For Mold Repair | Laser Wevelength | 1064nm |

|---|---|---|---|

| Electricity Demand | 220V /50Hz/60Hz | Output Power | 400W |

| Dimension | 1570*480*1400mm | Net Weight | 530kg |

| Laser Source | YAG Laser | Xenon Lamp | Made In China |

| Highlight | YAG mold laser welding machine,400 Watt mold laser welding machine,yag laser welding machine |

||

Tool & Die Mold Cavity Repair Mould Laser Welding Machine 400 Watt YAG Laser

- With ten directions flexible Angle and position adjustment ability. The control rod carries on stepless speed control to the motor in the laser head. It is suitable for repair welding at any Angle and position on all molds.

- For large size molds, there is no need for a workbench, and molds can be welded directly on the ground or forklift.

- Ceramic condenser cavity, high reflectivity, long service life.

- At the same time, it is equipped with precision worktable, which adopts electric lifting, so that small mold welding is convenient and flexible.

Observing system: Equipped with 3D microscope with cross tracking. The welding position can be magnified 10 times (optional 15 times, 20 times). The center of the tracking cross coincides with the center of the laser spot. With high speed liquid crystal light valve filter protection device. Protect welder's eyes from laser flicker fatigue.

![]()

Control system: Industrial microcontroller control, high stability, easy maintenance.

![]()

Gas protection system: Automatic synchronous argon protection system, to ensure no oxidation stains in welding parts.

| Model | ML-WY-M02 |

| Average laser power | 400W |

|

Max energy of single pulse |

15J |

| Laser wavelength | 1064nm |

| Pulse width | 0-20ms |

| Laser welding frequency | 0.5 -100HZ |

| Spot size range | 0.2-2mm |

| Welding wire | 0.1-0.8mm |

| Power Supply | 380VAC ± 10% / 50-60HZ |

| Power Consumption | 12 KW |

| Water pressure protection | ≤ 0.025MPa |

| Cooling water temperature | ≤ 35 degrees |

| Temperature protection | 45 degrees |

| Cooling water flow | 10L/min |

| Dimensional | 1000mm x 600mm x 1500mm |

| Weight | 560kg |

| Cooling Way | Water cooling |

| Laser Type | Pulse |

| Hazard Class | 4 Class |

Application:

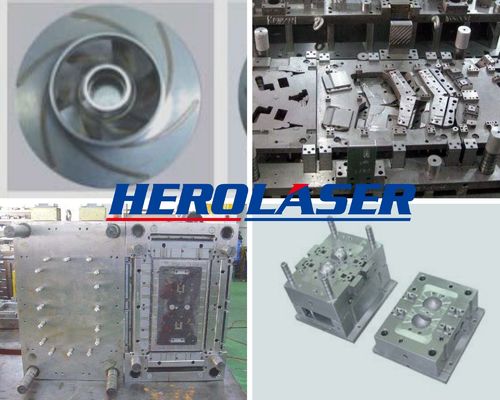

Specially for automobile mold, chassis mold, tire mold, household appliances plastic shell mold and other plastic, die casting mold and other large mold repair and welding design. Equipped with the lifting arm can be electrically lifted, 360 degrees of rotation, can weld 3 meters long, several tons of mold. And the device is equipped with pulleys for easy movement, easy to move to the injection molding machine for welding. The mold does not need to be unsealed. Manual worktable is also suitable for small and medium mold welding.

- 30% deposit before production and the balance 70% before shipment

- Ship in 7 days after 100% payment;

- Plywood box packaging

- We offer two warranty for laser source, one year for whole machine and lifetime maintenance services.

- Engineers available to service machinery overseas

- Free technical training in our factory

- Free sample can be sent to you

- Professional technical team 24 hours online

- Speeding offer within 8 hours quick response and free consulting.

- Free sample welding or testing is available

- Progressing solution design to all clients, including distributors and end users.

![]()