-

Handheld Fiber Laser Welding Machine

-

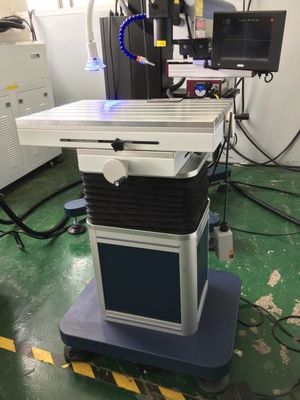

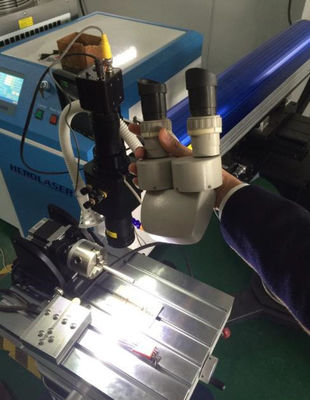

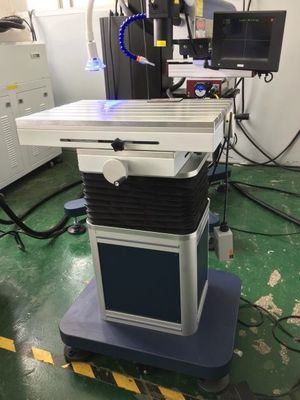

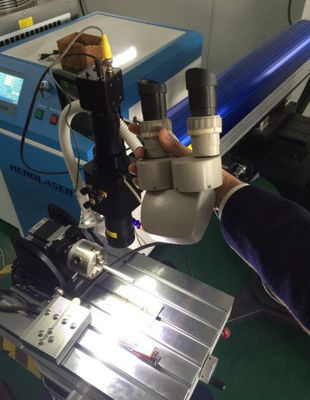

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

1064nm Mould Laser Welding Machine

| Laser Source | YAG Laser | Laser Wevelength | 1064nm |

|---|---|---|---|

| Max Energy Per Pulse (Joule) | 75J | Pulse Duration (sec) | 0.1S |

| Focal Length (mm) | 90mm | Pulse Repetition Frequency (Hz) | ≤50Hz |

| Mode (CW Or Pulse) | Pulse | Exit Laser Beam Or Beam Diameter At Lens (mm) | 0.2-2mm |

| Highlight | YAG Mould Laser Welding Machine,1064nm Mould Laser Welding Machine,1064nm laser beam welding tool |

||

1064nm Laser Welding Mould Laser Welding Machine No Heat Treatment Needed

Plastics processors will find that the alternative method of pulsed laser welding provides better results with less damage to the base material, so the mold will produce better quality parts and significantly longer service life after repair.

Laser welding is to irradiate a high energy density laser beam on two parts of the material, so that the local heating melt, and then cooling and solidification into one. Compared with traditional welding technology, laser welding has the following advantages:

1. Small heat-affected zone of laser repair welding will not lead to deformation of precision die, large welding depth, strong welding, sufficient melting, no repair marks, no depression in the joint of molten pool melt bump and matrix.

2. With a special microscope observation system for cross cursor, the magnification can be adjusted to achieve precise alignment.

| Model | ML-WY-M01 |

| Average laser power | 200W |

| Max laser power | 200W |

|

Max energy of single pulse |

75J |

| Laser wavelength | 1064nm |

| Pulse width | 0-20ms |

| Laser welding frequency | 0.5 -100HZ |

| Spot size range | 0.2-2mm |

| Welding wire | 0.1-0.8mm |

| Power Supply | 220VAC ± 10% / 50-60HZ |

| Power Consumption | 6000w |

| Water pressure protection | ≤ 0.025MPa |

| Cooling water temperature | ≤ 35 degrees |

| Temperature protection | 40 degrees |

| Cooling water flow | 10L/min |

| Dimensional | 1400mm x 1400mm x 1500mm |

| Weight | 340 kg |

| Cooling Way | Water cooling |

| Laser Type | Pulse |

Field of application:

Laser die repairing welding machine is to weld the special welding wire to the damaged parts of the die through the instantaneous high heat energy generated by the laser, and firmly weld with the original base material. After welding, it is processed into a smooth surface by EDM or grinding, so as to repair the die.

Widely used in die repair and metal parts repair, can weld a variety of die materials: S136, NAK80, 718, 738, P20, SKD-11, SKD-61, H13, W302, GS2344, GS2343, GS2082, etc.

- 30% deposit before production and the balance 70% before shipment

- Ship in 7 days after 100% payment;

- Plywood box packaging

- We offer two warranty for laser source, one year for whole machine and lifetime maintenance services.

- Engineers available to service machinery overseas

- Free technical training in our factory

- Free sample can be sent to you

- Professional technical team 24 hours online

- Speeding offer within 8 hours quick response and free consulting.

- Free sample welding or testing is available

- Progressing solution design to all clients, including distributors and end users.

![]()