Shenzhen Purple Horn Equipment Co., Ltd was established in 2004, is a national high-tech enterprise in China, engaged in the

research and development, production and marketing of laser equipment group of companies, has formed a complete series of

industrial laser equipment supply platform.

With a team of professional technical personnel,rich management experience, clear development direction to ensure our rapid growth

in the rapid development of the laser industry,we have established branches in Jiangsu, Zhejiang,Shandong, Chongqing and other

regions in China, and we have exported to 60 countries and have overseas agents in 10 countries. Our main products is Laser

Cleaning Machine / Laser Marking Machine / Laser Welding Machine / Laser Cutting Machine.

Products are widely used in electrical appliances, mobile communications, hardware products, tool accessories, precision

equipment, jewelry, glasses and watches, integrated circuits, craft gifts, plastic molds, medical equipment and other industries.

All Products

-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

12000 Million Watts Laser Welding Machine 20mm Steel plates ISO9001 Approved

Product Details

| Highlight | 12000 Million Watts Laser Welding Machine,20mm Steel Plates Laser Welding Machine,ISO9001 Handheld Fiber Laser Welding Machine |

||

|---|---|---|---|

Product Description

![]()

Products Description

Product introduction

Welding technology is a key technology in ship manufacturing and the development of shipbuilding industry. Welding working hours account for about 30%-40% of the total working hours for shipbuilding. The welding cost accounts for 30%-50% of the entire hull cost, Welding efficiency and welding quality will directly affect the production cycle, cost, and hull quality of ship manufacturing. The traditional welding process welding steel plate needs to be grooved and filled with solder to meet the welding requirements. The thicker the plate, the greater the bevel angle, it requires multiple processes to be fully welded. will be high solder cost,Long welding time ,Poor weld flatness and poor firmness for This process The traditional process of beveling requires at least 5 processes such as plasma cutting, grinding, drilling, milling, and

beveling. Transfer 4 times, 4-5 workers (positions) can be completed, it is time-consuming and inconsistent accuracy,Using a 10,000-watt welding machine, only need one person, no need to transfer, and high accuracy. It can be completed in one-third of the time of traditional craftsmanship, improve the quality and efficiency of manufacturing.

beveling. Transfer 4 times, 4-5 workers (positions) can be completed, it is time-consuming and inconsistent accuracy,Using a 10,000-watt welding machine, only need one person, no need to transfer, and high accuracy. It can be completed in one-third of the time of traditional craftsmanship, improve the quality and efficiency of manufacturing.

Certification

2.Steel plates above 20mm only need to open a quarter of the traditional groove angle, The groove gap is greatly compressed, and the solder cost is smaller.

3.The efficiency can be increased by 6-10 times, achieve the improvement of production efficiency and manufacturing accuracy and good Firmness.

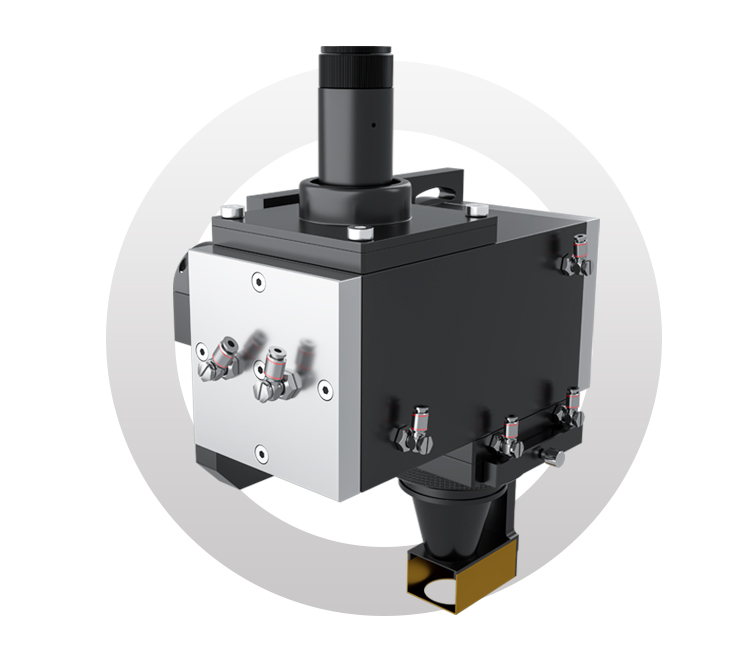

4.The 12000W laser welding machine has excellent processing effects in butt welds and long fillet welds.

1.20mm thick plate metal welding

2.High efficiency, 10 times faster

3.No need to open groove, low solder cost

4.Save labor cost

Applicable Industry

hardware

automobile

shipbuilding

aviation

wind power industry

construction machinery

Company Information

Characteristics

Packaging & Shipment

Our Services

---Pre-Sales Service

① Free pre-sales 7*24 hours rapid response services / cousulting ② Free sample testing / inspection ③ Free design of fixtures as customers / distributor required ④ Strict quality control for our products ⑤ Quick delivery time

---After-sales Services

① 2 year guarantee for laser source(people damaged are charged) ② Full technical support / by e-mail, call and video ③ Spare parts supply. ④ Free online training installation and operation ⑤ 12 hours quick feedback & after-sales services ⑥ ODM/OEM service

FAQ

1. What model does Purple Horn produce?

Production of Laser Welding series, Laser Cleaning series, Laser Cutting series and Laser New energy automation, etc.

2. What are the payment methods of Purple Horn Company?

T/T, LC, CAD, OA, Trade Insurance, Alibabapay

3. Does Purple Horn accept Acceptance?

Yes, we accept bank acceptances within 6 months, not commercial acceptances.

4. Can I visit the factory?

Available to have a visit to our factory at any time.

5. What can I get with the purchase of equipment?

Each machine has a set of standard accessories.

7. Can I go to the factory to test the machine before shipment?

Of course you can.

8. How is the delivery and shipment?

Ship in 7 days after 100% payment; Packaged with Plywood box.

9. How about your pre-sales service?

Provide quick response and free consulting services within 8 hours.

10.How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.

11. What are the advantages of laser cleaning machine?

1. Laser cleaning has the characteristics of no grinding and non-contact,

2. Cleanable organic pollutants,

3. Cleanable inorganic substances: metal corrosion, metal particles, dust, etc.

4. Application effects include: rust removal, paint removal, degreasing, cultural relics restoration, glue removal, coating removal and coating removal.

12. Is it easy to operate?

The operation is simple. When the power is turned on and the equipment is turned on, the cleaning can be carried out without chemical reagent, medium, dust and water.

3. Cleanable inorganic substances: metal corrosion, metal particles, dust, etc.

4. Application effects include: rust removal, paint removal, degreasing, cultural relics restoration, glue removal, coating removal and coating removal.

12. Is it easy to operate?

The operation is simple. When the power is turned on and the equipment is turned on, the cleaning can be carried out without chemical reagent, medium, dust and water.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes.

producing PET plastic containers and bottles in all shapes.

Recommended Products