Shenzhen Purple Horn Equipment Co., Ltd was established in 2004, is a national high-tech enterprise in China, engaged in the

research and development, production and marketing of laser equipment group of companies, has formed a complete series of

industrial laser equipment supply platform.

With a team of professional technical personnel,rich management experience, clear development direction to ensure our rapid growth

in the rapid development of the laser industry,we have established branches in Jiangsu, Zhejiang,Shandong, Chongqing and other

regions in China, and we have exported to 60 countries and have overseas agents in 10 countries. Our main products is Laser

Cleaning Machine / Laser Marking Machine / Laser Welding Machine / Laser Cutting Machine.

Products are widely used in electrical appliances, mobile communications, hardware products, tool accessories, precision

equipment, jewelry, glasses and watches, integrated circuits, craft gifts, plastic molds, medical equipment and other industries.

All Products

-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

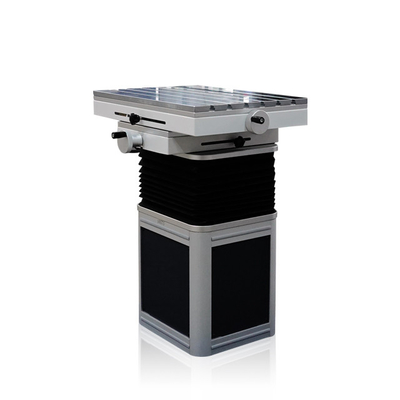

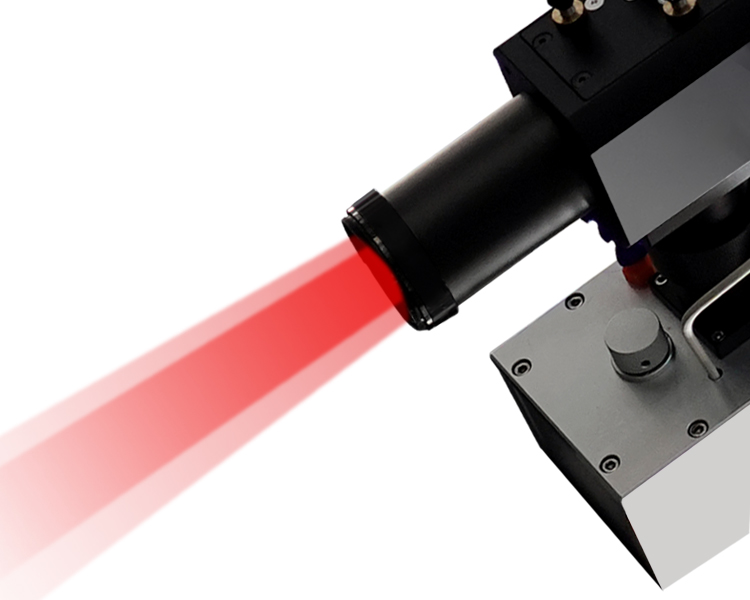

Mould Repairing Laser Welding Machine Nd YAG Pulse 0.1-0.3mm spot

Product Details

| MODEL | ML-WY-BP-DB-W200 | 3-axis Stroke Of Work Bench | X=300mm,Y=200mm(X,Y Can Be Adjusted Manually And Z-axis Can Be Lifted) |

|---|---|---|---|

| Bearing Of Work Bench | ≤200KG | Power Supply | 220V±10%/50Hz Or 380V±10%/50Hz |

| Laser Type | Nd:YAG Pulse | Adjusting Range Of Light Spot | 0.1~0.3mm |

| Highlight | Nd YAG Pulse Laser Welding Machine,0.3mm Laser Welding Machine,YAG Handheld Fiber Laser Welding Machine |

||

Product Description

Product picture

Parameter

Products Description

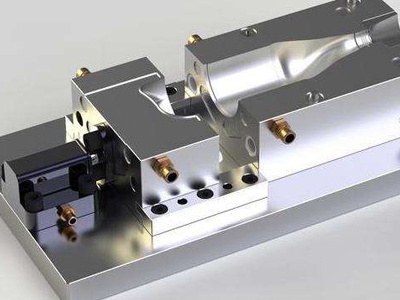

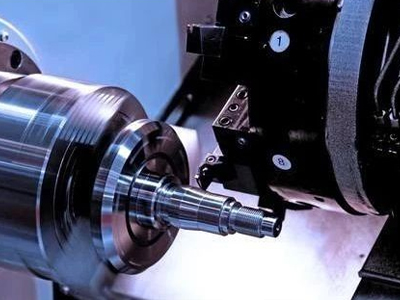

Purple Horn mould repairing laser welding machine series are specialized for the mold industry works, this model dedicated to replacing the traditional argon welder for repairing precision molds. All the key components of this machine are imported. The software operating interface use large LCD screen and display multi-languages interface, it is simple and easy to use for operator. Multiple presetting operating mode, also can program by users, permanent memory function, applicable to a variety of materials.

Characteristics

Model Features

1,Heat affected zone is small, little deformation for precision molds.

2,Welding depth is large, welding firmly. Sufficient fusion, no repairing traces. No dimple phenomena at combining position of

projection parts and bulge part of molten pool soluble material.

3,Low oxidation rate, the color of the processing parts is intact.

4,No stomata or sand hole disappeared after welding.

5,The welding parts can be processed, especially suitable for polishing requirements of the mold repair.

6,The processing parts can reach to 50 to 60 Rockwell hardness.

2,Welding depth is large, welding firmly. Sufficient fusion, no repairing traces. No dimple phenomena at combining position of

projection parts and bulge part of molten pool soluble material.

3,Low oxidation rate, the color of the processing parts is intact.

4,No stomata or sand hole disappeared after welding.

5,The welding parts can be processed, especially suitable for polishing requirements of the mold repair.

6,The processing parts can reach to 50 to 60 Rockwell hardness.

Repairing and welding for crack, corner breakage, touched edge and damaged sealing side of mold, precision injection molding, die-casting, stamping, stainless steel and other horniness.

Applicable Industry

Mold industry

Metalworking

Aerospace

Machinery manufacturing

engineering construction

Precision Industry

Company Information

Certification

Packaging & Shipment

Our Services

---Pre-Sales Service

① Free pre-sales 7*24 hours rapid response services / cousulting ② Free sample testing / inspection ③ Free design of fixtures as customers / distributor required ④ Strict quality control for our products ⑤ Quick delivery time

---After-sales Services

① 2 year guarantee for laser source(people damaged are charged) ② Full technical support / by e-mail, call and video ③ Spare parts supply. ④ Free online training installation and operation ⑤ 12 hours quick feedback & after-sales services ⑥ ODM/OEM service

FAQ

1. What model does Purple Horn produce?Production of Laser Welding series, Laser Cleaning series, Laser Cutting series and Laser New energy automation, etc.

2. What are the payment methods of Purple Horn Company?

T/T, LC, CAD, OA, Trade Insurance, Alibabapay

3. Does Purple Horn accept Acceptance?

Yes, we accept bank acceptances within 6 months, not commercial acceptances.

4. Can I visit the factory?

Available to have a visit to our factory at any time.

5. What can I get with the purchase of equipment?

Each machine has a set of standard accessories.

6. Can I go to the factory to test the machine before shipment?

Of course you can.

7.How is the delivery and shipment?

Ship in 7 days after 100% payment; Packaged with Plywood box.

8. How about your pre-sales service?

Provide quick response and free consulting services within 8 hours.

9.How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.

2. What are the payment methods of Purple Horn Company?

T/T, LC, CAD, OA, Trade Insurance, Alibabapay

3. Does Purple Horn accept Acceptance?

Yes, we accept bank acceptances within 6 months, not commercial acceptances.

4. Can I visit the factory?

Available to have a visit to our factory at any time.

5. What can I get with the purchase of equipment?

Each machine has a set of standard accessories.

6. Can I go to the factory to test the machine before shipment?

Of course you can.

7.How is the delivery and shipment?

Ship in 7 days after 100% payment; Packaged with Plywood box.

8. How about your pre-sales service?

Provide quick response and free consulting services within 8 hours.

9.How will you guarantee after-sales services?

We offer two years warranty for laser source, one year for the machine.

Recommended Products