-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

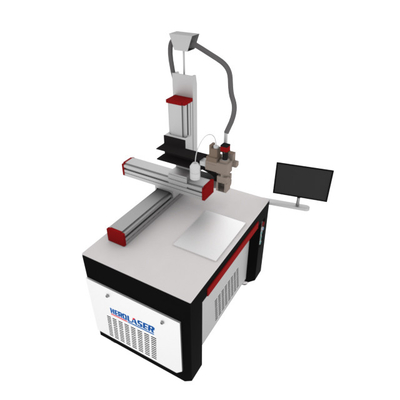

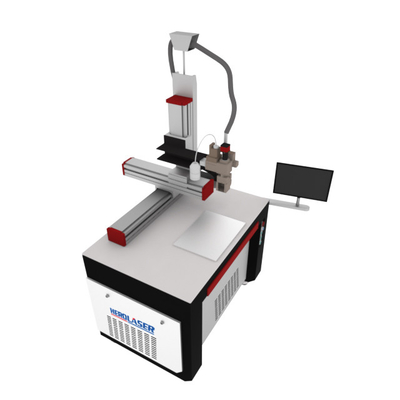

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

Mini Handheld Automatic Fiber Laser Welder Welding Machine For Industry

| Welding Thickness | 0.1-5mm | Laser Wavelength | 1074nm |

|---|---|---|---|

| Technical | Continuous/Pulse Wave Laser | Welding Depth | 0.5 - 2.5mm |

| Welding Gap | ≤0.5mm | Welding Speed | 120mm/s |

| Application Material | Metal / Cooper | Cooling Method | Water/Air Cooliing |

| Control | Manual/Automatic | Dimension | 1000mm*600mm*1700mm |

| Highlight | Purple Horn Fiber Laser Welder,500w Mini Handheld Laser Welder,Water cooling Fiber Laser Welder Machine |

||

Product Description

1. Mini Handheld Laser Welder is a new handheld laser welding system that gives fabricators more flexibility, precision, and ease of use compared to traditional welding products

2. Mini Handheld Laser Welder represents a paradigm shift due to its extremely small size and weight, as well as unique air-cooling. enablinge a more environmentally friendly welding process with low electric consumption, low noise operation, and reduction of consumables, clean up and scrap disposal.

3. Multiple nozzle options empower you to challenge a wide range of welding tasks including spot welding, butt welding, overlap welding, vertical welding, flat fillet welding, internal and external fillet welding.

4. At the same time, with the wobble welding technology and automatic wire feeding system, it perfectly solves the problem of thin plates, and plates with large gaps are difficult to be efficient and high-quality Difficulties in welding.

We have 4 kinds of machines :

1. Laser Marking/Engraving Machine;

2. Laser Welding Machine;

3. Laser Cutting Machine;

4. Laser Cleaning Machine.

| Model | ML-500w |

| Average laser power | 500w |

| Max laser power | 500w |

| Max energy of single pulse | 75J |

| Laser wavelength | 1064nm |

| Laser weld depth | ≤ 2mm |

| Pulse width | 0.3-20ms |

| Laser welding frequency | 0.5 -100HZ |

| Spot size range | 0.2-2mm |

| Welding wire | 0.1-0.4mm |

| Power Supply | 380VAC ± 10% / 50-60HZ |

| Power Consumption | 2KW |

| Water pressure protection | 0.025MPa |

| Cooling water temperature | 35 degrees |

| Temperature protection | 45 degrees |

| Cooling water flow | 10L/min |

| Dimensional | 1100mm x 900mm x 1200mm |

| Weight | 320kg |

| Cooling Way | Water cooling |

| Laser Type | Pulse |

Machine Features for handheld laser welding machine

2. High efficiency ,energy saving ,environment friendly and more safety operation.

3. The welding effect is good, the continuous emission laser mode is adopted, the welding point is uniform, the surface of the welding seam is very smooth and clean, and there is no need for secondary processing after welding.

4. Easy to operate and no need high experienced operators like arc welding, save you expensive technical labor cost.

5. No consumables, maintenance-free.

6. Welding speed: 3-5 m/min, which is 2-10 times the welding speed of manual arc welding.

7. A variety of hand-held welding heads are available to meet various requirements such as metal parts, internal welding, right-angle welding, narrow-side welding, large spot welding, and so on.

8. Minimal heat input, small heat-affected zone, reduce welding distortion caused by heat conduction.

9. Workers are highly efficient and will not feel tired after long welding. No UV light ,no ozone when operating, keep operators health.

10. Using a handheld laser welding gun, the welder can work comfortably.

| Item | Traditional welding | Laser welding |

| Heat effect | Very high | Low |

| Welding deformation | Big | Small |

| Welding strength | Good | Excellent |

| Post-processing | Polish | No or Rarely polished |

| Welding speed | Common | fast |

| Applicable materials | Stainless steel,carbon steel,AL, galvanized sheet | Stainless steel,carbon steel,AL, galvanized sheet |

| Consumables | Many | Less |

| Operation difficulty | Difficult | Simple |

| Operator safety | dangerous | Safe |

| Environmental | Polluted | Environmental |

| Welding fault tolerance | Good | Good |

| Wobble welding | NO | Yes |

| Adjusted beam width | NO | Yes |

| Welding quality | Bad | Excellent |

![]()

Gun Features for handheld laser welding machine

![]()

![]()

![]()

Applications

![]()

![]()

![]()

![]()

Certificates

![]()

Company Introduction

![]()

ABOUT Purple Horn

Shenzhen Purple Horn Equipment Co., Ltd was established in 2004, is a national high-tech enterprise in China, engaged in the research and development, production and marketing of laser equipment group of companies, has formed a complete series of industrial laser equipment supply platform.

2. Full technical support / by e-mail, call and video

3. Spare parts supply.

4. Free online training installation and operation

5. 12 hours quick feedback & after-sales services

6. ODM/OEM service

A1:T/T, LC, CAD, OA, Trade Insurance, Alibabapay, Also accept bank acceptances within 6 months