-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

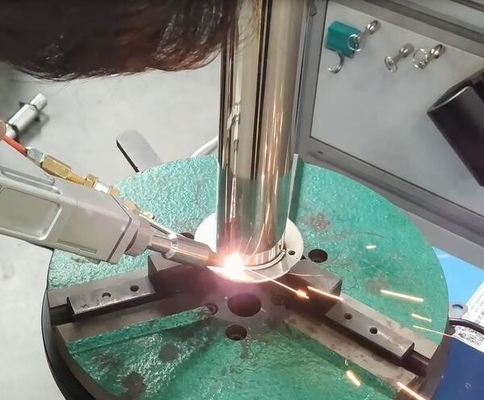

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

Portable Handheld Fiber Laser Machine , Aluminium Stainless Steel Wire Mesh Welder

| Welding Thickness | 0-3.3 MM | Laser Wavelength | 1064nm-1070nm |

|---|---|---|---|

| Technical | Continuous / PULSED | Welding Depth | 0.5 Mm - 2.5 Mm |

| Welding Gap | ≤0.5MM | Welding Speed | 0-120mm/s |

| Application Material | Aluminum, Stainless Steel Carbon Steel Copper Iron | Cooling Method | Water /Air |

| Control | Manual/Auto | Dimension | 1100 Mm*600 Mm*1700 Mm |

| Highlight | 1064nm Fiber Laser Machine,1070nm Fiber Laser Machine,Stainless Steel Aluminium Wire Mesh Welder |

||

Product Description

Laser welding is a method of welding by using focused laser beam as energy to bombard the heat generated by the weldment. Because of the optical properties of laser, such as refraction and focusing, laser welding is very suitable for welding micro parts and parts with poor accessibility. Laser welding also has the characteristics of low heat input, small welding deformation and immunity from electromagnetic field.

Machine Features for handheld laser welding machine

(1) The heat input can be reduced to the minimum required amount, the metallographic variation range of the heat affected zone is small, and the deformation caused by heat conduction is also the lowest.

(2) The welding process parameters of 32mm thick single pass welding have been verified as qualified, which can reduce the time required for thick plate welding and even save the use of filler metal.

(3) There is no need to use electrodes, and there is no concern about electrode pollution or damage. And because it is not a contact welding process, the wear and deformation of the machine can be minimized.

(4) The laser beam is easy to focus, align and be guided by optical instruments, can be placed at a proper distance from the workpiece, and can be guided again between the machines and tools or obstacles around the workpiece. Other welding rules cannot be used because of the above space restrictions.

(5) The workpiece can be placed in a closed space (under the control of vacuum pumping or internal gas environment).

(6) The laser beam can be focused on a very small area and can be used to weld small and closely spaced parts,

(7) The range of weldable materials is wide, and various heterogeneous materials can also be joined with each other.

(8) It is easy to carry out high-speed welding automatically, and can also be controlled by digital or computer.

(9) When welding thin materials or thin diameter wires, there will be no reflow problem like arc welding.

(10) It is not affected by magnetic field (arc welding and electron beam welding are easy), and can accurately align the weldment.

(11) Two metals with different physical properties (such as different resistance) can be welded

(12) No vacuum or X-ray protection is required.

(13) If piercing welding is adopted, the depth to width ratio of weld bead can reach 10:1

(14) The unit can be switched to transmit the laser beam to multiple workstations.

![]()

| Model | ML-500w |

| Average laser power | 500w |

| Max laser power | 500w |

| Max energy of single pulse | 75J |

| Laser wavelength | 1064nm |

| Laser weld depth | ≤ 2mm |

| Pulse width | 0.3-20ms |

| Laser welding frequency | 0.5 -100HZ |

| Spot size range | 0.2-2mm |

| Welding wire | 0.1-0.4mm |

| Power Supply | 380VAC ± 10% / 50-60HZ |

| Power Consumption | 2KW |

| Water pressure protection | 0.025MPa |

| Cooling water temperature | 35 degrees |

| Temperature protection | 45 degrees |

| Cooling water flow | 10L/min |

| Dimensional | 1100mm x 900mm x 1200mm |

| Weight | 320kg |

| Cooling Way | Water cooling |

| Laser Type | Pulse |

![]()

Machine Features for handheld laser welding machine

Gun Features for handheld laser welding machine

1. The laser quality is good, the electric welding speed is faster, and the welding is solid and beautiful. We provide customers with electric welding solutions. The safety coefficient is high. The electric welding joint is only effective when touching metal materials. The touch screen switch has the magnetic induction function of human body temperature.

2. The portable water-cooled heat dissipation gas welding gun conforms to the ergonomic design scheme. It is easy to move, and the welding distance is longer. It can be used for electric welding at any position of the product workpiece. The photoelectric conversion is high efficient, low energy consumption, and the actual operation is simple and easy to learn. Ordinary workers can enter the post through short-term drills without professional welding teachers. Long term application can greatly save production costs.

3. The portable laser welding equipment has the advantages of less harm, less deformation, blackening, no trace, large welding depth, sufficient melting, solid and reliable. Portable laser welding equipment can be used for electric welding from a random perspective, and can be used to weld all kinds of disordered products and irregular large and medium-sized product workpieces. Electric welding with random focus shall be completed.

![]()

![]()

![]()

Applications

![]()

![]()

Aviation Parts Domestic Appliance

![]()

![]()

Elevator Manufacturing Auto Parts

Branches

![]()

Certificates

![]()

Company Introduction

![]()

ABOUT Purple Horn

Shenzhen Purple Horn Equipment Co., Ltd was established in 2004, is a national high-tech enterprise in China, engaged in the research and development, production and marketing of laser equipment group of companies, has formed a complete series of industrial laser equipment supply platform.

2. Full technical support / by e-mail, call and video

3. Spare parts supply.

4. Free online training installation and operation

5. 12 hours quick feedback & after-sales services

6. ODM/OEM service

A1:T/T, LC, CAD, OA, Trade Insurance, Alibabapay, Also accept bank acceptances within 6 months