-

Handheld Fiber Laser Welding Machine

-

Mould Laser Welding Machine

-

Automatic Laser Welding Machine

-

Robot Laser Welding Machine

-

Laser Rust Removal Machine

-

Laser Cleaning Machine

-

Portable Laser Cleaning Machine

-

Laser Paint Cleaner

-

Handheld Laser Cleaning Machine

-

Sheet Metal Fiber Laser Cutting Machine

-

Laser Tube Cutting Machine

-

High Precision Laser Cutting Machine

-

Fiber Laser Marking Machine

-

CO2 Laser Marking Machine

-

UV Laser Marking Machine

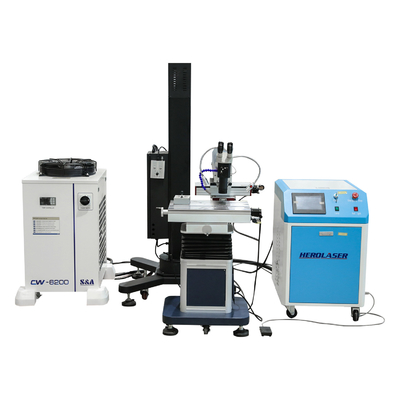

Laser Welder for Die Mold Repair Repairing Equipment Mould Welding Machine

| Laser Working Material | ND/YAG | Maximum Average Laser Output Power | 400W |

|---|---|---|---|

| Rated Output Power | 400W | Laser Wavelength | 1064nm |

| Spot Size | 0.3-3.0mm | Pulse Width | 0.1-20M |

| Pulse Frequency | Spot Welding | Welding Method | 1-100HZ |

| Water Pressure Protection | ≤ 0.025MPa | Maximum Energy Of A Single Pulse | 120J |

| Maximum Power Of The Entire Machine | 12KW | Control System | Touchpad |

| Aiming And Positioning | Microscope, Red Light | Electricity Demand | 380V/single-phase/50HZ/60A |

| Cooling Water Temperature | ≤ 35 ° C Water Temperature Protection 45 ° C | Cooling Water Flow Rate | 10L/min |

| Applicable Materials | Titanium, Aluminum, Copper, Zinc, Gold, Silver | ||

| Highlight | 1064 nm Mold Laser Welding Machine,50 Hz Mold Repair Laser Welder,120 x 150 mm Laser Mould Welding Machine |

||

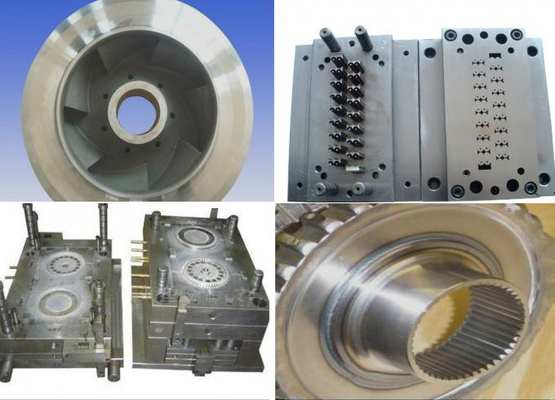

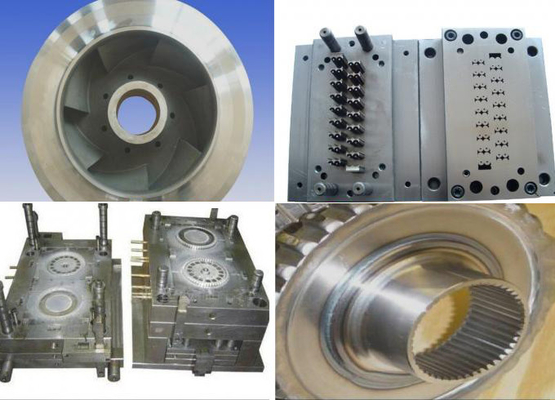

About Repair Mould Laser Welding Machine

Laser mould welding machine is use the high energy of heat that instantaneously produced by laser to melt the special-purpose

welding wire and connect it with the damaged parts of the mould , so it can connect with the original material firmly, after that

there will form a refacing by electric spark and grind & cutting and some other processing and so the mould is repaired. Purple Horn

developed special type of laser mould welding machine for mould industry on the base of several years’experiences of laser

welding development. It can repair tiny parts of the moulds such as blisters, crack, burst pieces and attrition precisely. It is widely

used in the industries of mobile phone, digital, car and so on. It can repair all kinds of Mould Steel, Beryllium Copper, Red Copper

and extremely hard alloy material. Small heat affected zone can avoid mould deformation. Deep welding makes the connection

firm. Sufficiently melting leaves no repairing traces and no concave slot on the joint between raised part and matrix.

![]()

![]()

Features:

- It adopted imported ceramic condenser cavity from UK, high reflectivity, strong power, and extremely long services life.This model occupied the largest proportion in domestic market for its proven technology and stable performance.It equipped with 1.5P high power special cooling water system is able to support the machine to work longer hours with high power in good condition.

- The base of the wortable uses electric lifting for up and down movement.

- The moving unit of the worktable is equipped with precise ball bearing bar and linear lead rail.

- It is light weight and flexible with precise positioning

- The designed of the machine, such as the adjusted laser arm; laser head & the attach equipments is to meet the varied requirement of tool & die; mould repair jobs.

Field of application

It is applicable to make patch welding on large, middle, small size plastic mold or die-casting mold used in industries like shell making industry,

automobile industry, rubber industry and home appliance industry. This model is the first choice for processing services provider to proceed site

processing for customer.

Machine Advantages

1. Fiber laser with high electro-optical conversion efficiency

2. Anti-high anti-reaction ability

3. Maintenance-free operation

4. Wide modulation frequency range

5. Fast speed, high precision and delicate appearance.

6. The diameter of the solder joint can be adjusted according to the requirements, and the heat

7. affected zone is small, which will not cause the deformation of precision products;

8. suitable for all sizes of products, density welding will not have pores and trachoma, and can be directly ground and polished.

Samples display:

![]()

![]()

![]()

Machine Main Parts and Pictures:

![]()

![]()

![]()

![]()

Delivery and Shipment:

- Ship in 10-15 days after 100% payment;

- Plywood box packaging

Payment Terms:

- Prepay 30% when we receive the Purchase Order;

- Complete the rest 70% payment before the cargo leave Purple Horn.

After-sales service terms

- Two Years warranty for Laser source, One year warranty for Whole Machine;

- Purple Horn can train1-2 engineers for customer for free in Purple Horn’s factory.

- In One year of purchase, such as machine failure is a quality problem ,free maintenance. The service does not include human or environmental factors, customers fault and supplies section.